Corefix Uncovered

Corefix is Metex’s iconic dot & dab/cavity wall fixing specifically designed for fixing heavy items to walls with plasterboard attached over blockwork with adhesive (also known as drylining or “dot and dab.”) The easily recognisable red plugs are now well established in major retailers including Selco, B&Q, Screwfix and Bauhaus in Germany.

But what’s the idea behind it, how did it come about and how do you know if it’s right for your project? In this article we take an in-depth look at Corefix’s technical features and development.

The Origin Story

Corefix inventor, Metex Online’s Director Daniel Bamford, noticed the need for specialist cavity wall fixings when fitting kitchen cabinets at home: “I tightened the brackets up and then noticed that I couldn’t install the wall units because the wall had become bowed inwards. I had to loosen the screws to bring the wall back straight to be able to fit the cabinets… Does not give confidence!”

Metex (back then consisting of Daniel and fellow Director Daniel Hopkins) manufactured a prototype injection moulding tool to test the concept in the correct material.

Initially, they used the moulded prototypes and built a shelf, mounted to a wall with brackets. “We loaded the shelf with concrete blocks up to more than quarter of a ton! Becoming nervous, we stopped the test as we did not want to damage the floor in the building that we were using for testing”, Daniel describes.

After testing the fixings in house, an independent laboratory tested the Corefix fixings, which produced independently verified test data that we can stand behind!

The recommended Safe Working Load is calculated by taking the maximum load from the test data and dividing this by a Factor of Safety. This ensures that installers can use Corefix with confidence.

Well aware of tradespeople’s difficulties in fixing to dot and dab walls, Daniel & Daniel attended trade shows to demonstrate the fixings, filmed videos and demonstrated to stockists. In parallel, they conducted a market trial, and the feedback confirmed their own findings – that Corefix simply works: “The initial feedback from customers was fantastic, they recommended Corefix to friends and colleagues. After the prototype tool and testing/validation phase, we quickly progressed to production tooling.”

Sales have grown since, with market awareness resulting in Corefix being a top five selling fixing in the leading UK fixings suppliers!

But what is a “dot and dab” wall?

Corefix solves the problem of fixing heavy items to a dot and dab wall, but what is a dot and dab wall?

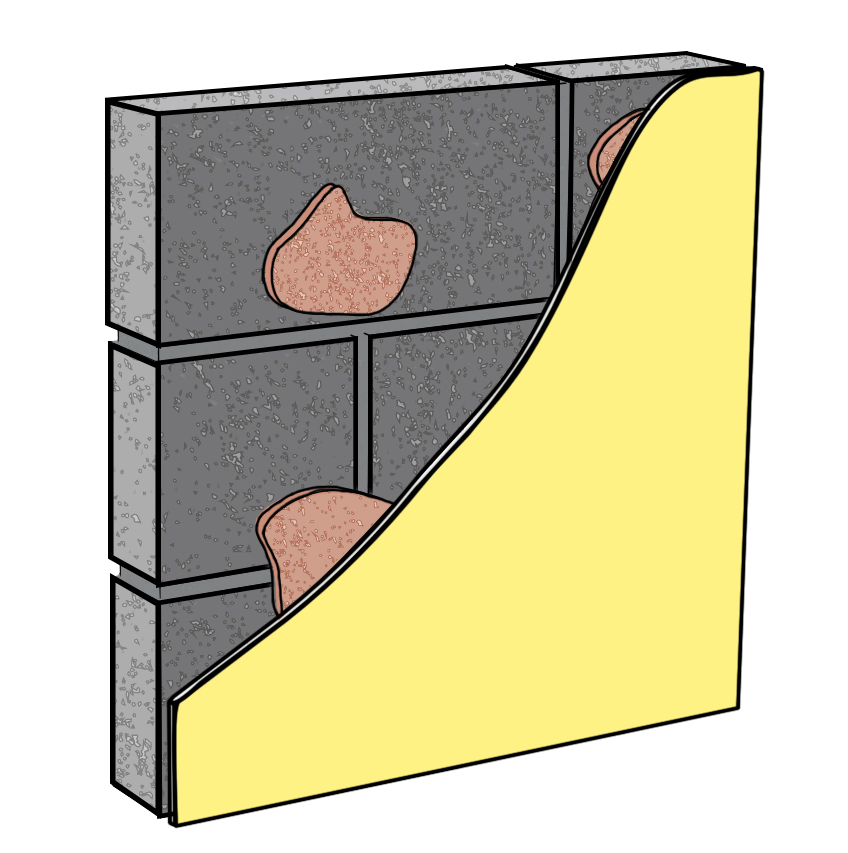

A dot and dab wall (sometimes referred to as a cavity wall) is a masonry or blockwork wall that has been clad internally with plasterboard. The wall is partially hollow, with a void between the plasterboard and masonry. Unlike older walls which are traditionally solid, most modern houses constructed from the 1930s onwards have this type of cavity walls, where there is a small gap between the brickwork and plasterboard. These types of walls are called “dot and dab” walls because of the dabs of adhesive commonly used to secure the plasterboard. It’s these dots of adhesive that space the plasterboard away from the masonry and leave the cavity or gap behind it.

Previously, the options for fixings things to cavity walls have been either just fixing to the plasterboard or fixing through the plasterboard to the blockwork with frame fixings – but both methods unfortunately have their own issues.

What about just fixing to the plasterboard?

Fixing lighter loads like light fittings or picture frames to cavity walls is generally not a problem using just plain plasterboard fixings. However, with heavy items like cupboards, wall mounted televisions, shelves or radiators, the situation becomes a bit trickier.

No matter how strong a heavy-duty plasterboard fixing is, the weak point is the plasterboard itself as the material alone often can’t bear the weight and there’s a risk of the plasterboard crumbling or distorting over time – even more so if the plasterboard is thin, old or moisture-damaged! If you do end up having to fix something heavy to plain plasterboard, the best thing to do is either fix to the timber studs (if it’s a stud wall) with wood screws, or use more fixings than you normally would to spread the load as much as possible.

Using plasterboard fixings on dot & dab walls also means issues when it comes to brackets. Heavy items fixed close to a wall are less of a problem since the main force the fixings need to deal with is the force pushing straight down, aka the “shear” force. However, with heavy items mounted on a bracket like in the figure above, the load isn’t just applying force straight down, but also pressing towards the wall at the bottom of the bracket and pulling outwards at the top (also known as “tensile” force).

In other words, a lot of force gets applied on small areas on your wall. With plasterboard fixings, the bottom of the bracket can end up crushing the plasterboard inwards with nothing resisting it. With Corefix, the tensile force instead ends up pushing against the steel core connecting to blockwork – saving your plasterboard.

Letting the blockwork take the load

To play it safe, you should generally anchor heavy items to the masonry behind the plasterboard. However, this can cause another problem. A conventional expansion plug and screw, or “frame fixing”, will usually impart a compressive point load when the screw is tightened, which can crush the plasterboard into the cavity behind it. Not only that, but it also potentially damages the wall finish and can even visibly distort the wall, which is not at all good if you later want to move the item you originally fixed there.

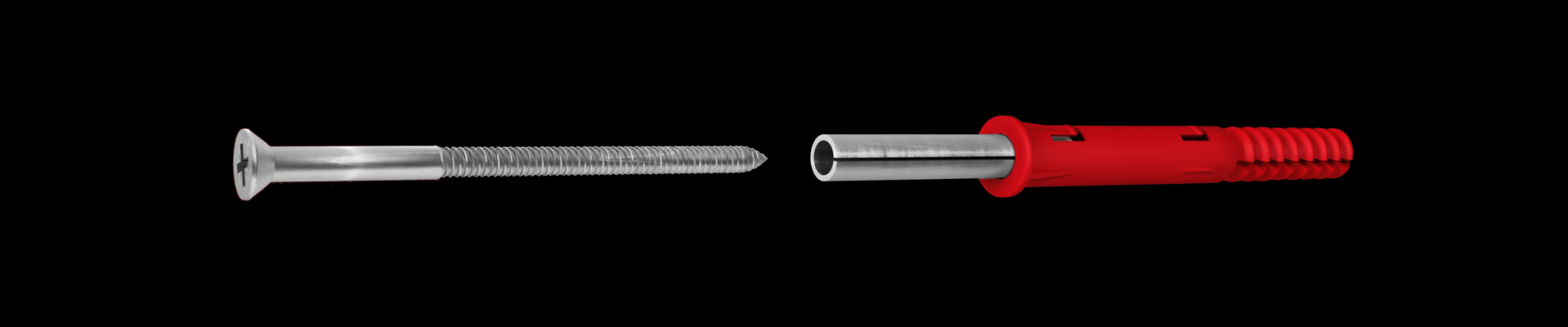

Corefix works a bit differently: It consists of a patented wall plug, made of an engineering polymer, a heavy-duty steel core and a screw. The steel core bridges the plasterboard cavity, transferring the load from the plasterboard to the blockwork behind. It also means the plasterboard stays straight and doesn’t bow inwards when the screw is tightened.

As previously mentioned, Corefix cavity wall fixings were originally designed for securing kitchen cabinets without the risk of crushed or distorted plasterboard, but they can also secure TVs, boilers, and heavy-duty shelving, and have been tested to over 250kg without failure.

The patented plug is designed with anti-rotation ribs and serrations to ensure the fixing is secure. The steel core directs the load to the blockwork wall behind the plasterboard, rather than simply relying on the strength of the plasterboard. This means Corefix works equally well in other wall materials too, such as brick, block and light-weight concrete. The Safe Working Load (on 4 fixings) is 100kg in brick and blockwork, and 73kg in thermalite or aerated concrete.

Installation Tips

Corefix is quick and easy to install with standard tools – there is no need for specialist drivers or other equipment. You only need a 10mm masonry drill, a screwdriver and a hammer, and a fixing usually only takes about a minute to install.

- Check for wires and pipes. Wires are usually close to plug sockets and switches, often moving vertically or horizontally away from them. The easiest way to check for wires and pipes is to use a detector, available from most hardware stores. If in doubt, don’t carry on any further!

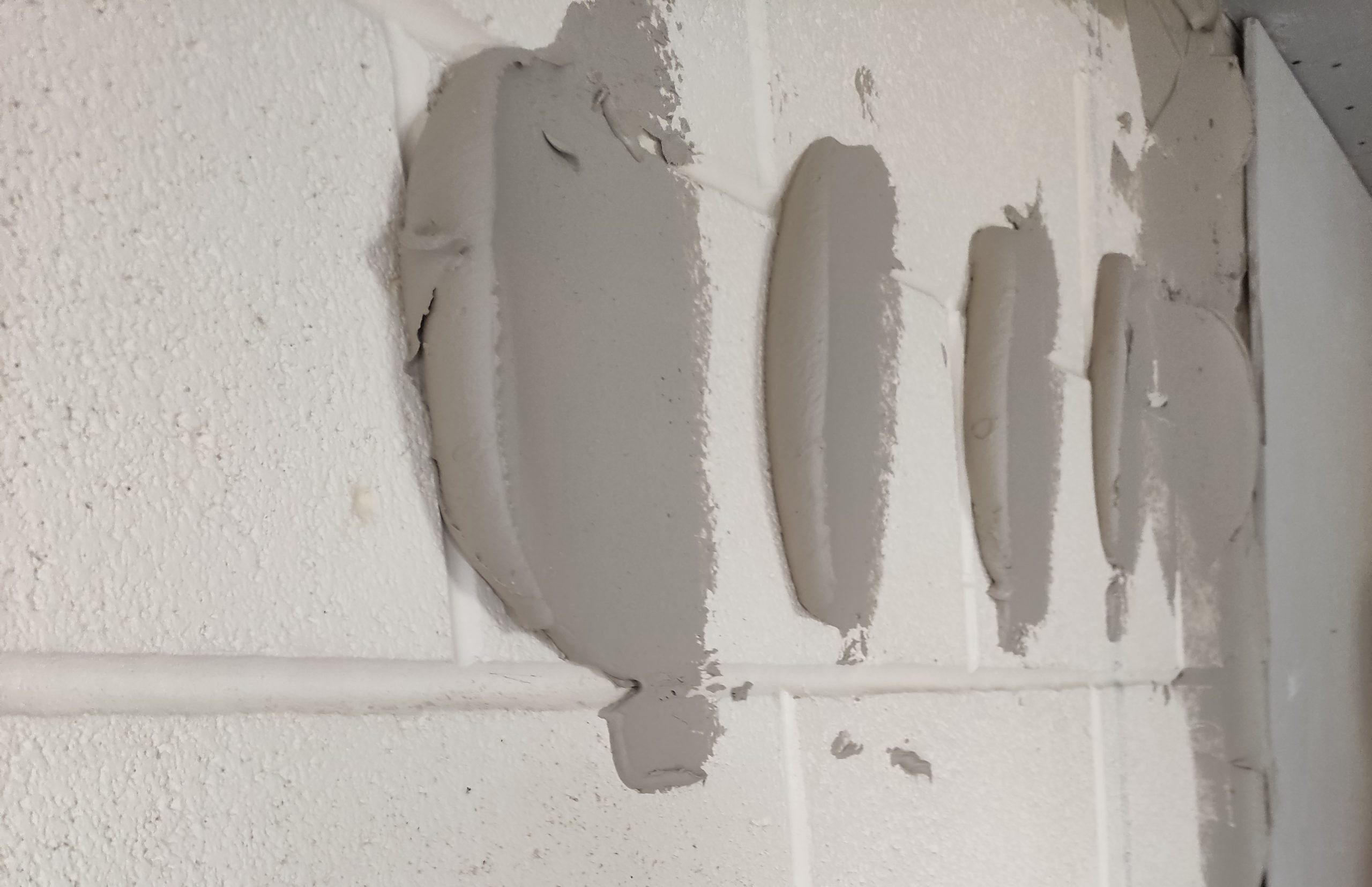

- Drill a 10mm hole through the plasterboard into the blockwork behind, ensuring a depth of at least 100mm and remove any dust which may get in the way of the fixing.

- Tap the Corefix plug in place, making sure the lip (flange) sits flat against the plasterboard wall.

- Tap the steel core home until it is level with the plug.

- Use the included screw to secure your wall support.

There are a few extra tips you can make use of: For example, if you’re unsure about getting a tight fit for the plug, or are working with aerated concrete, you can always drill a 9mm hole for the plug instead of a 10mm one.

You’ll also need to consider the thickness of the bracket you’re fixing – with the standard Corefix 100, the maximum fixture thickness is 10mm. If you’re fixing something thicker, go with the Corefix 120 as its longer screw allows for fixtures up to 30mm thick.

Bear in mind that the maximum overall distance from the outer face of the plasterboard to the blockwork for both varieties of Corefix is 45mm. If you’re unsure about the thickness of your plasterboard, or the width of the cavity behind it, you may need to drill a small pilot hole first to determine if Corefix is suitable for your project.

If you’re installing Corefix near an open edge of a block, for example close to a window frame, avoid drilling too close to the edge of the block – a minimum of 65mm is a safe distance. However, you won’t need to worry about this if you’re installing into solid blockwork. If you’re installing Corefix into a stone wall or very dense concrete, drilling can be tougher and take longer – make sure you use a fresh masonry drill bit and a hammer drill if you have one available.

If you’re wondering how Corefix might work out for your project, check out a recent case study on using Corefix for hanging up an expensive guitar collection!

Corefix fixings are available from B&Q, Screwfix, Ironmongery Direct and other reputable stockists.

Find out more in our Fixings Knowledge Base!