Liquid Screed vs. Traditional Screed

Liquid or pumpable screeds are a relatively new invention and can be an excellent alternative for traditional sand and cement screeds. Their popularity is increasing, primarily because they can be laid to a thinner depth and are far quicker to lay than traditional screeds, and they’re especially popular in use with underfloor heating. But what exactly is liquid screed, what’s it made of and how is it different traditional screed? How do you know which screed is right for your construction project and budget? Read on to find out.

What is a Liquid Screed and How is it Different to a Traditional Screed?

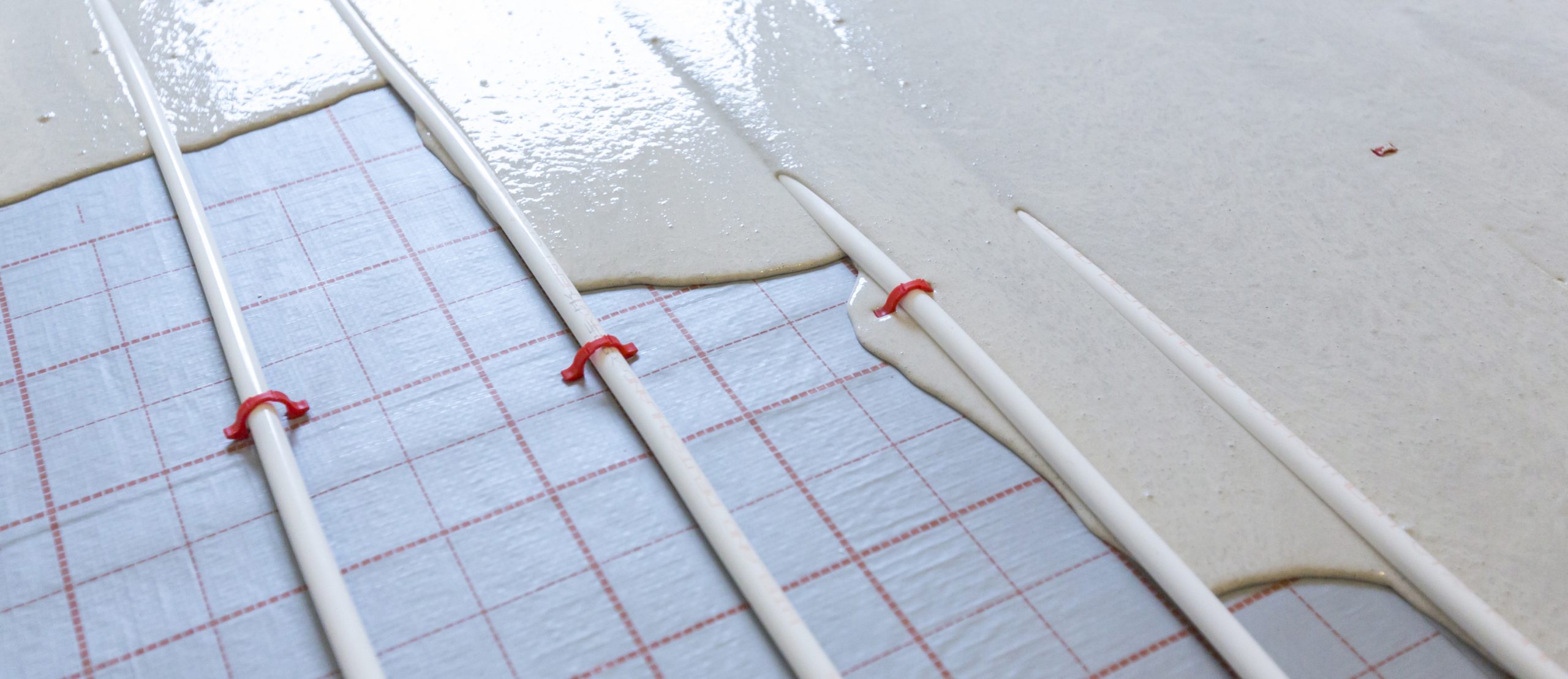

Screeds are not a structural element of your building; they are applied over the flooring surface to provide a smooth, level and flat surface that the finishing materials, such as carpeting or tiles, are applied to. If you are using underfloor heating it will be laid under the screed, which is poured over the top.

Traditionally a screed would have been laid by shovelling in the screed mix and then levelling it with a screeding bar and/or polyurethane float. Liquid screeds are ready-mixed, delivered to site where they are then pumped into the room and poured across the floor. This liquid finds its own level so will be perfectly level and will be hard enough to walk on in about 72 hours, although it will take longer before it is completely dry.

Different Types of Liquid Screed

The most common type of liquid screed has calcium sulphate as the active ingredient, making up around a third of the volume. This becomes gypsum when water is added, and as a result can be referred to as a “calcium sulphate screed”, “gypsum screed” or even “anhydrite screed” which refers to the form of the mineral – anhydrous calcium sulphate – which is used.

More recently cement based pumped screeds have become available. These can be pumped like a gypsum screed, but do not have the downsides.

Different manufacturers and suppliers (Tarmac, Breedon, Cemex, etc) have different proprietary products (Topflow Screed, Belitex, Cemfloor, etc) so there is variation, but they will broadly fall into these following categories:

- Traditional cement screed

- Pumpable calcium sulphate screed

- Pumpable cement-based screed

The choice of which one to choose is based on the different pros and cons of the various options.

Benefits of Traditional Screeds

- Possible to self-mix so you can ensure the right amount and are not dependant on an outside delivery

- Can be ready mixed and delivered to ensure consistency while reducing significant amounts of effort and time

- Possible to create a flat surface which is not level; this can be necessary particularly in wet rooms for example

- Material costs are cheap – certainly the cheapest of the screed options

Benefits of Pumped Calcium Sulphate Screed

- Very quick to lay/pour – a 25m2 area will take around 20 minutes start to finish

- While the material costs are typically about twice that of traditional screed because it is so quick to lay – savings can be made on labour and time which means the cost are broadly the same

- Can be laid as thin as 35mm which reduces material costs and means that heat from under-floor heating is more effective

- It is very level – much more so than is possible with a traditional screed even with an experienced professional

- Calcium sulphate is less prone to shrinking which means there is less need for expansion joints, and large tiles laid on it will be less prone to cracking

- Under-floor heating is more effective, not only because it is not heating a larger depth/volume of screed, but because the liquid flows all around the pipes so heat transfer from the pipes are more effective

Disadvantages of Calcium Sulphate Screed

- The floor surface needs to be prepared before the finish floor material can be installed. A substance called laitance needs to be removed

- The drying time is broadly similar to a traditional screed, and care needs to be taken during the first 72 hours where drying should not be too fast

- Most suppliers will not allow DIY laying; they will insist that an experienced contractor be used to measure and pour the screed

Benefits of Pumped Cement Screed

There are many general benefits which are similar to a pumped calcium sulphate screed vs a traditional screed, over and above these are as follows:

- Once dry they do not need surface preparation, (whereas a calcium sulphate screed does), before laying the finished floor surface

- They have substantially quicker drying times than calcium sulphate

Disadvantages of Pumped Cement Screeds

- Availability is currently limited

- The material cost is about 20% higher than a calcium sulphate screed although in a similar way this can be made up with a reduction in labour time

- They require more expansion gaps than a calcium sulphate screed

It is easy to see why using a liquid screed has become so popular. It is quick and requires much less labour than a traditional screed. It is not effective on a small scale or where there needs to be a slope on the floor, but almost anywhere else it is fast becoming the preferred solution.

For information on high-quality screeding tools used by professional screeders and groundworkers to level, dapple and spray free flowing liquid screeds, click here or find out more in our Knowledge Base!