What is the difference between a dot and dab cavity and a stud work plasterboard wall?

As a manufacturer and supplier of specialist fixings for dot and dab cavity walls we are constantly being asked whether they are suitable for plasterboard walls which they are, providing there is a solid brick or block wall behind the plasterboard.

However, many walls found in houses are not built this way, especially on the upper floors, where they will commonly use what is called a stud work construction.

To ensure you obtain the correct cavity wall fixing products we thought it may therefore be helpful to explain the differences between the two methods of construction.

What is a dot and dab wall?

A dot and dab wall also known as a drylined wall is where plasterboard is attached to a solid brick or block inner skin of a cavity wall (or in certain cases a solid wall) by the use of dabs of adhesive or wooden battens. This creates a small gap between the plasterboard and the supporting wall.

Stud work on the other hand is where a wooden frame is constructed to create the room partitions and the plasterboard is then attached to the framework. This is favoured in upper floors of houses as it reduces cost and simplifies the supporting wall requirements at ground level because it is much lighter.

Find out if you have a stud wall or a dot and dab wall?

Here are a few clues to help you determine what sort of wall you are dealing with if it has a plasterboard finish.

- Unless your property has a timber frame construction, the ground floor walls, even internally, are almost certainly going to be of a dot and dab construction

- Dot and dab walls always sound less ‘hollow’ if you tap them

- Dot and dabs walls are typically thicker as there has to be a solid wall plus the void behind the plasterboard and the plasterboard itself

The common term used for the fixing used for attaching heavier objects to these types of wall such as shelves, televisions, radiators and all manner of cupboards and units is the rawl plug – not a raw plug as it is often mistakenly called. This covers a multitude of different styles of which Corefix is just one and you may also come across terms such as wall plug / wall anchor and drywall anchor.

Incidentally a good way of remembering the correct term of rawl plug is that it gets its name from John Joseph Rawlings who invented this simple yet universally used fixing way back in 1911. The basic concept is that these plugs fit in a drilled hole and enable a screw to be securely fixed into material that is either porous or brittle or that would otherwise not support the weight of the item.

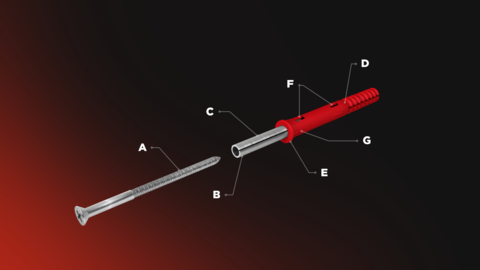

Plasterboard is a typical example and even if you have a solid wall behind it, as in the case of a dot and dab wall, the plasterboard can still be crushed or become deformed at the point of maximum load if you use a standard rawl plug. This is because the rawl plug and the plasterboard alone are taking all the weight. Corefix works differently; it has a steel core that bridges the cavity so that the weight is more evenly distributed allowing a safe working load of up to 90kg to be supported by just four Corefix fixings (independently tested and verified) although during our own in house tests we have achieved up to 250kg– without failure.

So if you are looking for a safe and reliable wall fixing capable of supporting heavy loads then Corefix is an ideal product to use. If you have any questions at all please don’t hesitate to contact us. You can email us or call us for free on 0800 130 3646.

Corefix is represented by Metex – delivering Innovation for Construction.