Spotlight On Angle Grinder Safety

Even though the no. 1 purpose of angle grinders is grinding metal, they also come in handy when cutting metal or bricks, blocks and paving slabs. However, they’re also one of the most dangerous tools used in industry and agriculture, with over 5000 documented injuries related to their use each year.

In fact, ‘The Royal Society for the Prevention of Accidents’ Accident Surveillance Systems data ranked angle grinders as the third most dangerous tools, with 5400 injuries recorded annually!

Many of these are head and eye injuries, but arms and legs can also get in harm’s way. For example, a 49-year-old man ended up with a deep gash in his foot while cutting metal without wearing safety boots, and a very unlucky 65-year-old got multiple fractures in his legs and hands after an angle grinder accident caused a nearby fuel tank to explode!

But this is not just a home DIY problem – accidents with angle grinders and other rotating tools are also common in construction and engineering.

Injuries are most often caused by shattering of the abrasive wheel, but they can also result from contact with the wheel, kickback, clothing or hair entanglement, sparks or electric shock.

Also, cutting using a high-speed disc or blade can cause projectiles like fragments of concrete, stone etc. to fly off in all directions and cause injury.

So how can you avoid injuries when using an angle grinder? Let’s take a look at rotating tool safety.

Protective Clothing

The first step to keeping yourself safe when using an angle grinder is wearing appropriate PPE. This includes work gloves and boots, safety goggles, hard hat and a dust mask. Make sure the safety goggles shield both the front and side of the eye.

Angle grinders also produce a lot of heat, and if you’re cutting or grinding metal, it’s also a good idea to wear a face shield, gloves and fire-retardant clothing to protect yourself from hot sparks. Be also mindful of any fumes (depending on the material you’re cutting or grinding) and wear a respirator, especially if you’re working indoors or in a confined space.

Hearing protection is also a must, as angle grinders are quite loud and can lead to hearing damage or loss, especially if you use them often.

Make sure your clothing isn’t too loose and flapping to avoid entanglement, and ensure long hair is securely tied back.

Shards and Projectiles

As mentioned earlier, most angle grinder injuries are a result of shards from a shattered wheel. To avoid shards from a shattered disc becoming lodged in your face and costing you an eye or worse, you need to take care of the tool and use it appropriately.

Old and worn discs are the most prone to shattering. In addition to checking their general condition, they usually have an expiry date and maximum speed stamped on them, often on the inner metal ring, so check those as well before use. Don’t use discs or blades beyond their maximum speed or ones that are expired, and replace your discs regularly. Bear in mind that most angle grinders run at a fixed speed of around 11,000 RPM.

Also – please don’t try to be an inventor! Improvising attachments or trying to “customise” your angle grinder can lead to injuries, as the disc can break if it’s not suitable for the angle grinder it’s mounted on. Using parts or accessories not meant for angle grinders, or any homemade contraptions, will not only put you at risk of injury but also likely void the warranty on your machine!

Removing the safety guard may seem tempting if it feels like it’s getting in the way, but the guard is there specifically to contain disc if it shatters and direct any disc debris away from the user. These days, many manufacturers offer guards which can be moved and locked into different positions, allowing you to get into tight areas, so ensure the guard is locked in place and no one is in the potential path of any flying shards if the disc does break.

It’s also a good idea to use an angle grinder with a “dead man” switch which you need to keep in the on position while in use, so if you were to let go of the grinder, it would switch off, reducing the risk of injuries. You should also ensure that you don’t do any cutting around glass surfaces (windows, doors, patio doors.)

Contact With the Blade and Kickback

Apart from deflecting disc debris, the angle grinder’s safety guard is also there to protect you from contact with the disc, which can lead to lacerations and even lost fingers or toes, so once again, keep it on! The guard should cover half of the disc and be positioned between the disc and the operator.

Another common dangerous mistake is not using the side handle. Despite comments of it getting in the way, having one hand on the body and one on the side handle allows you much more control of the tool which means less chance of accidents! Wear suitable work gloves to keep a good grip, and always remain alert and focused when using the angle grinder.

If you’re cutting bricks, blocks or paving slabs, it can be tricky to cut in a straight line as the disc is constantly biting and catching and can easily run off course. To avoid this, it’s best to use a cutting jig or a straight edge guide such as a piece of angle steel or a spirit level. DIY Doctor recommends clamping the straight edge in place along the cutting line.

If you’re using a grinder or rotating saw to cut bricks, blocks or paving slabs on site without a jig, it may be tempting to get the job done quickly and just hold them in place on the ground with your foot while cutting. However, if you’re doing this on an uneven surface the risk of the blade binding or kicking back is very high and puts your limbs and eyes in danger!

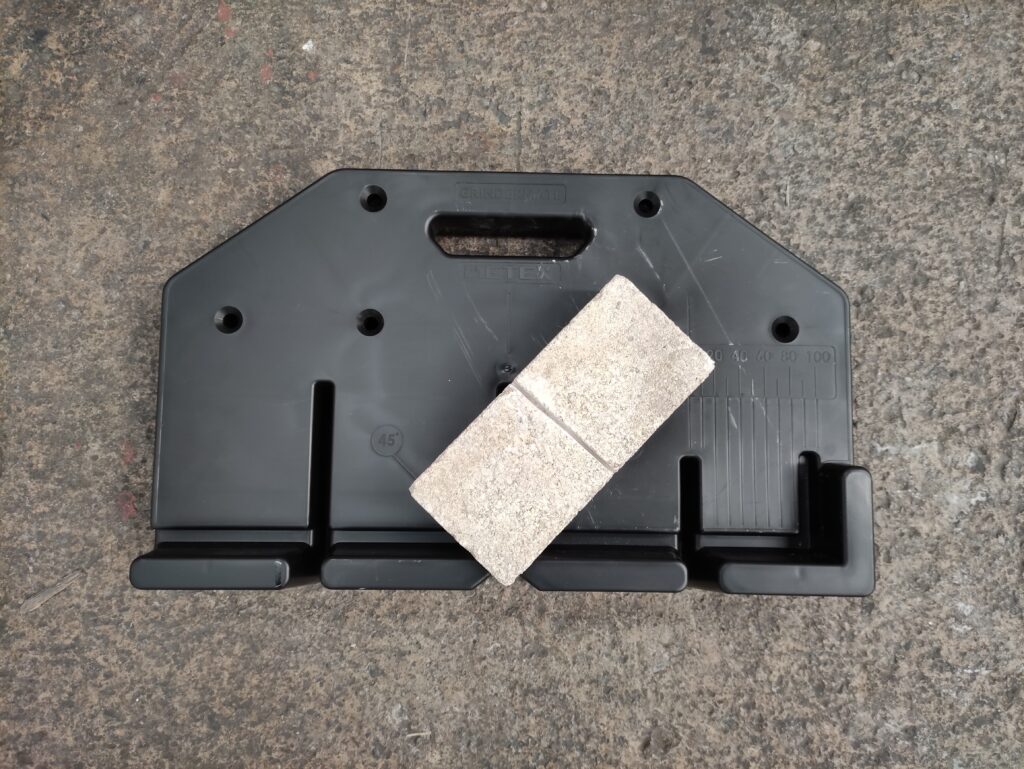

A simple portable cutting jig like Grindermate (pictured above) is safer for your toes and isn’t large or awkward to move around. It’s a light and stable cutting platform for brick and block paving, marked for half brick and angled cuts, and you can just grab it from the van, place it on the ground on a stable surface, and get cutting whenever you need it.

Grindermate has guidelines marked on it for 45 degree and half brick cuts, and the gaps in the platform let the blade pass through. The middle section is designed to support a diagonally placed brick or block pavior, and the corner keeps a brick in place for half cuts. All you need to do is place a brick or block in the position you need, and cut down towards the bottom edge of the cutting jig.

Grindermate is available from Screwfix, B&Q, Selco, FFX, Cromwell and other good tool suppliers.

Kickback is also a risk if you are using the wrong wheel or running at the wrong speed. You can reduce the risk by making sure you are using the right wheel for the material and have your tool at the right speed. Dull and badly set discs also increase the risk of accidents from kickback, so make sure you know how to change them correctly (get trained if necessary) when they get worn out.

Sparks, Dust and Fumes

When cutting or grinding metal, angle grinders can produce sparks – and yes, they can start fires if they hit something flammable. Sparks tend to fly especially if you’re using an old worn disc or an older angle grinder model, and they can travel for more than 4 metres.

Obviously the first thing to do to protect yourself is to wear protective clothing, mask, goggles, fire retardant gloves and a face shield. The angle grinder’s safety guard also directs sparks away from you. Make sure there are no flammable materials or objects nearby, like old rags, paper, sawdust, steel wool, dry grass or hay, wood chips, petroleum-based fumes or fuel tanks!

Dust or fumes caused by cutting or grinding can also be hazardous to your health, depending on the material you’re working with. Several different metals can give off toxic fumes when in contact with high heat, like zinc, aluminium and magnesium.

For example, zinc fumes can be caused by grinding or cutting galvanised steel, and can cause flu-like symptoms including fever, nausea, fatigue, head & muscle aches, shortness of breath, dry or sore throat, chest pain, dizziness, coughing, and sometimes a sweet or metallic taste in the mouth. Symptoms of a more severe poisoning can also include a burning sensation, shock, convulsions, bloody diarrhea, rash or vomiting, and need prompt medical attention. With materials that could produce toxic fumes, using a respirator is a must.

Dust produced by cutting or grinding is also a significant health issue, as an estimated 12,000 lung disease deaths in Great Britain each year are thought to be linked to past exposures to different types of dust at work, mostly from chronic obstructive pulmonary disease (COPD), mesothelioma and lung cancer (both asbestos-related and non asbestos-related).

You should always wear at least a dust mask when using an angle grinder or rotating saw, and work in a well-ventilated area. Dust suppression equipment can help reduce airborne dust particles by spraying a fine mist of water, and also helps with on-site visibility. Large towable units and spraying systems are available for construction sites and quarries for example, but for smaller jobs or self-employed tradespeople, a pressurised dust suppression water bottle connecting directly to the tool is a simple – and much cheaper – solution. The Manta S1400 dust suppression water bottle, for example, takes 14 litres of water and plugs into most popular tool brands with a universal hose connector.